AGE CCPP Natural Gas Fired CCPP (200 MW, 3 x SIEMENS SGT800 GTG + l x STG)

AGE CCPP Natural Gas Fired CCPP (200 MW, 3 x SIEMENS SGT800 GTG + l x STG)

Project Location:Denizli, TurkeyENPRODE’s Project Responsibilities;

» EPCM- Engineering, Procurement and Construction Management

» Bankable and Technical Feasibility Study

» Conceptual, Basic and Detailed Engineering & Design

» Procurement Consulting

» Construction Management

» Commissioning and Start-up

AGE signed an agreement with ENPRODE Engineering in June 2010 for the Design, Engineering, Procurement and Construction Management (EPCM) of all project phases from the conceptual design up to commercial start-up of their 200 MW Combined Cycle Power Plant investment.

The Power Plant was constructed on land owned by AGE located in Sarayköy, which is a town 22 km to Denizli.

The Plant configuration comprises; 3+1 Gas Turbine Combined Cycle technology and consists of three Gas Turbines, Heat Recovery Steam Generators (HRSG), one Steam Turbine and one Air Cooled Condenser (ACC) in accordance with the equipment performance. AGE CCPP was put into commercial operation in Simple Cycle mode on 27 July 2012 upon Ministerial Acceptance

MAIN TECHNICAL PARAMETERS

Overall Plant Data | |

| Gross power output | 200 MWe |

| Gross electrical efficiency | 54.5% |

| Fuel type | Natural gas |

Gas Turbine | |

| Type | Siemens SGT800 |

| Site rating | 44877 kWe |

| Exhaust Gas Flow | 459 t/h |

| Exhaust Gas Temperature | 549 °C |

Heat Recovery Steam Generator | |

| Type | Vertical Gas Flow, Drum - Type HRSG |

| Boilers (HP) | Eco, Evaporator, Superheater |

| Boilers (LP) | Eco, Evaporator, Superheater |

Steam Turbine | |

| Type | Multi-Stage Condensing Steam Turbine |

| ST power output | 64,5 MWe |

| HP Steam | 80 bar/520 °C |

| LP Steam | 75 bar/280 °C |

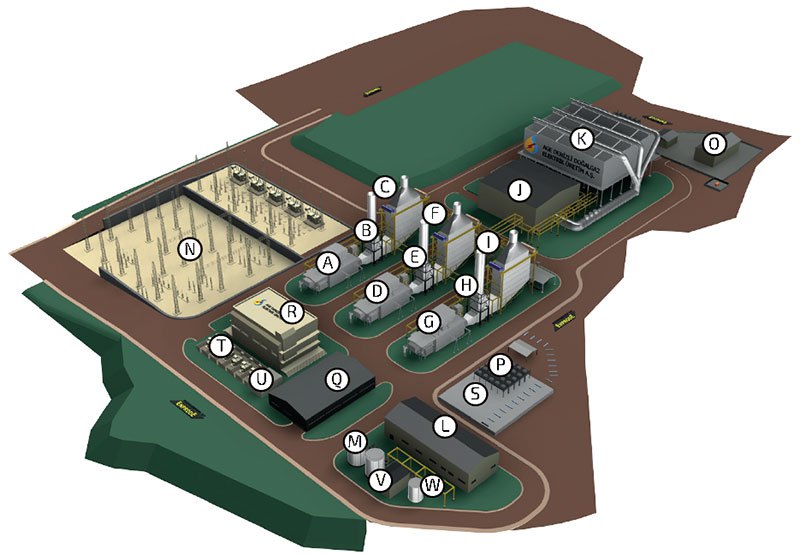

Power Plant Key

A. Gas Turbine #1

B. By-pass Stack#l

C. Heat Recovery Steam Generator # 1

D. Gas Turbine #2

E. By-pass Stack #2

F. Heat Recovery Steam Generator #2

G. Gas Turbine #3

H. By-pass Stack #3

I. Heat Recovery Steam Generator #3

J. Steam Turbine Building

K. Air Cooled Condenser

L. Demineralized Water Plant

M. Demineralized Water Storage Tank

N. Air Insulated Switchyard

O. Gas Regulating & Metering Station

P. Dry Air Coolers

Q. Storage Building

R. Main Control Building

S. Raw Water Reservoir

T. Service Transformers

U. Emergency Diesel Generator

V. Ultra-Filtration Building

W.Potable Water Storage Tank

A. Gas Turbine #1

B. By-pass Stack#l

C. Heat Recovery Steam Generator # 1

D. Gas Turbine #2

E. By-pass Stack #2

F. Heat Recovery Steam Generator #2

G. Gas Turbine #3

H. By-pass Stack #3

I. Heat Recovery Steam Generator #3

J. Steam Turbine Building

K. Air Cooled Condenser

L. Demineralized Water Plant

M. Demineralized Water Storage Tank

N. Air Insulated Switchyard

O. Gas Regulating & Metering Station

P. Dry Air Coolers

Q. Storage Building

R. Main Control Building

S. Raw Water Reservoir

T. Service Transformers

U. Emergency Diesel Generator

V. Ultra-Filtration Building

W.Potable Water Storage Tank

English

English